Big. Small. We do it all.

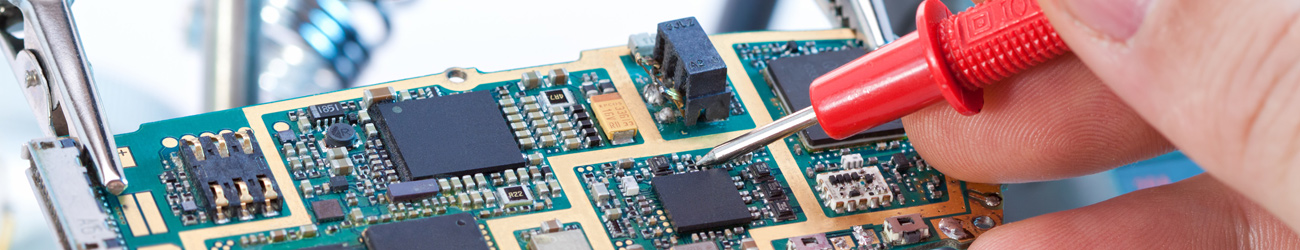

Our team takes great pride in our Electronic Manufacturing Services, which includes the most efficient and advanced equipment in the Midwest. Thanks to our ability to operate two SMT lines, we can easily fulfill both high and low quantity orders in order to serve large corporations as well as start-ups. Our industry experience includes these partners:

- North America’s largest car wash OEM

- World leading telecommunications company

- Electronic voting machine manufacturer

- Airline thermal printer OEM

- World’s largest railroad company

- Residential and commercial gas meter OEM

- Medical laboratory OEM’s

- Pull tab vending OEM

- Leading lift gate OEM

- Agriculture irrigation company

Capabilities

With a full line of advanced manufacturing equipment housed under one roof, TSI is capable of filling orders from 10 to 100,000. Our services include but are not limited to:

- Printed circuit board assemblies

- Through-hole and SMT

- Box builds/full product assemblies

- Cable/wire harness assembly

- PCB modifications

- UL listed products

- Prototypes

- High mix/low volume

- Large production runs

- Wave soldering

- Board washing

- Chip programming

- Conformal coating

- Potting

- IPC-A-610 adherence

- RoHS or Non-RoHS

- Automated optical inspection

- Solder paste inspection

Quality Certified

TSI has earned ISO 9001:2015 certifications and adheres to IPC-A-610 standards. We provide multiple quality checks including solder paste inspections, automated optical inspections and functional testing. We also deliver products on time and on budget, provide excellent customer service from start to finish and adhere to RoHS standards.

Our Manufacturing Equipment

MyData/ MYCRONIC MY600 Jet Printer

- Unbelievably fast, precise and allows TSI to produce complex boards, achieve high-precision solder joints, with a speed of more than one million dots per hour

- Non-contact nozzle that jets with high precision makes every solder paste deposit perfect, reducing the need for re-working and increasing overall throughput.

- Dot volume and diameter are easy to control, with the same, repeatable result with a wide mix of components.

MyData/MYCRONIC MY100 SXE SMT equipment (Two SMT lines)

- 21,500 components per hour

- Handles 01005’s, Flip Chips, QFP’s, and BGA’s

- Enables TSI to easily increase volumes to meet customer needs

Mirtec Automated Optical Inspection (MV-3)

- 5 camera desktop AOI system

- Supports a four mega pixel digital color camera technology

- Integrated INTELLI-BEAM laser inspection system

- Extremely accurate defect detection

Selective Wave solder Machine

- Programmable solder and flux control

- Quick change between RoHS and lead alloy

- Solution for many soldering challenges

Electrovert Wave Soldering Equipment (Vectra ES2)

- Allows TSI to achieve the best solder joint quality, maximum topside hole fill, and zero defect soldering

- 18-inch wide capacity

Heller Reflow oven

- 14 zones

- RoHS capable

- PC controlled

Board Washer

- Heated, high-pressure water for cleaning top and bottom of the PCB

- Closed-loop water purification

- 18-inch wide capacity

Dymax Conformal Coating and UV curing oven

Potting Equipment

We adhere to ESD Standard S20.20-2007. The floor is tested using a Megohmmeter, all assemblers utilize heel and wrist straps, ESD dissipative mats cover work surfaces and shelving, and all employees regularly attend ESD training.